I came to rug hooking as a shepherd and hand spinner, searching for ways to use my ever-growing stash of yarn. There weren’t a lot of resources for yarn hookers in the Pacific Northwest at that time, except for a Claire Murray shop in Poulsbo, Washington. Heaven! Thirty-some years and over a hundred rugs later, I can hardly believe my luck, happily discovering that little shop.

Over those years, I met people at fiber events who would ask me to look at a damaged old rug, or an unfinished rug begun by a relative long gone. As I worked on those pieces, I wrote about them in my blog. Soon the requests to repair old rugs came in unbidden over the internet.

I never advertised that I did rug repair. I can only assume that rug owners found me that way. But having googled for myself what kind of information is available on repair of old hooked rugs that I… (oh, what’s the nice way to say it?) disagree with, I finally decided to write this book.

A few years ago, I was fortunate to get to see the Unicorn Tapestries in the Musée de Cluny, the famous Medieval Museum, in Paris. Sitting in that

quiet, cloistered room, surrounded by those magnificent wall-sized woolen tapestries, I noted that in the lower sections, the colors seemed a little brighter. I learned that over the centuries, the tapestries had rotted on the bottom, and the museum had carefully restored those lower sections.

Judging from the advice I found on the internet about repairing hooked rugs, you might have thought the museum should have chopped off the bottoms of the iconic textiles, or slapped some latex on the back to keep them from falling apart!

I don’t claim to be an expert on museum artifacts, only a humble rug hooker. Someone with a basic understanding of the way hooked rugs are made, and how to restore the damage from decades of wear and tear. Hopefully, you will find the examples in this book helpful. For every rug hooker, there will be a different style, a different set of skills. I do my repairs with yarn. Others apply their skills with wool fabric. Differences are good. They give people choices. But let’s first agree on the fundamentals, shall we?

When I first started rug hooking, I read all the books and magazines I could get my hands on but couldn’t find much instruction on yarn hooking, specifically. Through trial and error, and publications like Rug Hooking Magazine, I was able to translate those techniques to yarn. I even discovered that there are things you can do with yarn that you can’t do with wool fabric. Repairing rugs can be one of them.

In Pearl McGown’s day, good wool fabric was cheap and plentiful. Yarn, not so much. But of course, times are always a-changing and there has never been more great yarn to be had at reasonable prices than right now. Yarn is available in a plethora of colors and textures, so you don’t have to do as much dyeing to get the colors right.

Some of the yarns I used to finish Cascabel, a rug that was originally hooked with wool fabric strips on burlap. More about this rug in Chapter 8: Unfinished Business.

In Yorkshire, many weavers in the early days (late 1700s) worked in their own cottages, either on their own or a rented loom. In the process of weaving many remnants of woolen yarn were left, in short pieces about 9”to 18” long, too short to be of value for further cloth weaving, and these ‘thrums,’ as these were called, became by custom the property of the weaver, the wool being often supplied by his employer or the man who took the finished cloth and paid for the labor of weaving. In the opinion of a former Yorkshire weaver with whom I have talked, the constant accumulation of these loom ends of woolen yarn logically led to the invention or at least the adoption of some way of utilizing them, other than disposal by sale as rags or waste.

William Winthrop Kent, The Hooked Rug, 1930

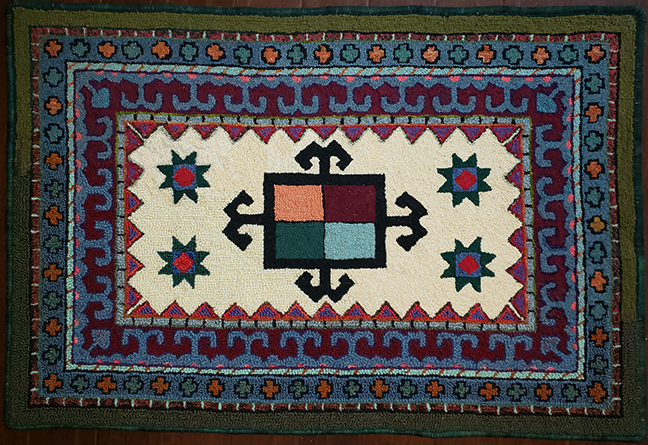

Tsela, 24.5”x37.” Wool fabric strips on burlap.

This rug is a perfect example of how much easier it can be to repair or finish a rug with yarn, even if it was originally hooked with fabric strips. This geometric design got kicked around for a while on eBay, but didn’t get much traction. You can certainly see its potential, but not many people have the wherewithal to finish it.

Tsela, 24.5″x37.” Finished with yarn.

There are 17 colors of wool fabric strips in this rug. Without going to the dyepot, I was able to match 14 of the colors out of my own yarn stash. The other three were found when I brought samples of the wool to my local yarn store. You literally have to put your nose right up to this rug to figure out which side was hooked with fabric and which was hooked with yarn. There is no store, online or brick and mortar, where you will find 17 colors of woolen fabric today in those exact colors. With fabric, you pretty much have to dye to get those colors, or search online for dyed wool fabric and take what you can find.

Admittedly, I have an extensive stash, which consists of yarn and dyed carded wool for spinning. I’m sure there are fabric hookers out there whose stash of fabric strips rivals my stash of yarn. But add to that the challenge that most rugs that we repair are aged and worn, it’s quite difficult to repair with new wool fabric, and make it look old. Yarn has a very diffuse appearance. I have found that it blends into the surrounding rug in a way that is far less noticeable than new wool strips.

Pictured above are Ewenique, Patons Bulky, Reynold’s Lopi, Rowan Big Wool, Halcyon Deco, Halcyon Rug Wool, Halcyon Botanica, Briggs & Little Super, Peace Fleece, Cascade Ecological, Universal Deluxe Chunky, Araucania, Sensations Licorice, New Zealand Woolpack, Rustic Rainbow, Heirloom Romney, Jacob’s Pride and handspun yarns, just to name a few!

Most yarn companies today have at least one brand that works for rug hooking. What you’re looking for is worsted weight to bulky yarns that aren’t slippery. If you’re looking at a yarn label, any yarn that knits 3.5 to 4 stitches per inch works great for rugs. So even if you’re not a whiz at dyeing, you can collect an impressive array of yarns that will work for rug repair.

Figure that you will need 4 ounces of yarn per square foot of hooked area.

When hooking with fabric strips, you must use 100% wool, but not so with yarn. As long as the yarn is thick enough and not slippery, you can hook with it. Of course, there is no fiber in the world that is as easy to dye as wool, so wool is still king in my book.

I’m a big believer in having all of my colorful stuff up on shelves in my workshop, where I can tell at a glance how much I have, and in what colors. Walking into my workroom is like going shopping! If your stash is kept in bags or boxes, under the bed, in a closet, or stuffed in your couch cushions, you aren’t going to know what you’ve got. You’ll probably go out and buy new yarn, because you’ve forgotten all the treasures you’ve already acquired.

Yarn organized by color and type.

I would be remiss if I gave you the impression this is what my workroom looks like all the time. Usually, it’s not so tidy, but everything is out where I can see it. It’s like the inside of my brain. Kind of chaotic at times, but at least I know where everything is!

If space is a problem for you, at least invest in a few clear plastic storage boxes, and stack your skeins inside them, so when you pull the boxes out, you’ll have a good idea of what you’ve got.

Dyed, carded wool, ready to be spun. With handspun yarn, you can blend colors or ply different colors together for subtle effects.

One thing that yarn is especially good for is monochromatic designs and shading. There are over 100 breeds of sheep, which come in a dizzying array of whites, blacks, greys, browns and reds. These colors don’t fade in the sun or bleed when washed. You can also overdye them to create seamless shading. You can buy yarn in natural colors online, but this might be a good time to make friends with a hand spinner!

There are spinning guilds in every state in the union, and in most other countries, too. By getting on their mailing lists, you may discover annual fiber events in your area. You might be able to find the exact color and texture of carded wool fiber you’ve been looking for. Buy exactly the amount you will need (4 oz per sq. ft.), there’s no waste if the fiber is already carded. It’s a good chance for cross pollination, too; maybe the spinner would like some rug hooking done in exchange for spinning up your yarn!

Miranda, 23”x29.” Handspun yarn in natural colors on linen. Designed and hooked by Judy Taylor.

The yarns in Miranda were spun from many natural colored breeds: Southdown, Texel, Wensleydale, Scottish Blackface, Shetland, Suffolk, Karakul, Romney, Navajo, Jacob, Mohair, Corriedale, Iceandic, Herdwick, Masham, Manx Loaghtan, CVM, Finnish Landrace, Perendale, Alpaca, Norwegian Vilsau, Swaledale, Lincoln, Border Leicester, Dorset Horn, Devon, Cheviot, Black Welsh Mountain, Cormo, Teeswater, Falkand, Bluefaced Leicester, Grey Gotland, Coopworth and Poodle (yup, Poodle!).

Cat With Kittens, 61”x32,” wool yarn. Courtesy of Linda Rosen Antiques. Notice the edge is bound with fabric, very helpful for its survival.

I assume that readers of this book already know how to hook rugs, but possibly haven’t had much experience hooking with yarn. I have included a quick primer on basic yarn hooking techniques in Chapter 11: Working With Yarn. I do my repairs with yarn, because it’s much easier for me to match colors and textures in a way that is less noticeable (more about that later).

However, if you are reading this book, hoping to repair your grandmother’s treasured rug but haven’t yet learned the craft of rug hooking, I would strongly encourage you to check out the other books in this series, Joy of Hooking (With Yarn!) and Rug Hooker’s Guide to the YARNIVERSE! More information on these books can be found at www.judytaylorbooks.com and www.littlehouserugs.com.

Maizie (top) and Daisy (bottom) Each measures 20”x30”

This pair of rugs has spent it’s whole life side by side, exposed to the same amount of traffic and sunlight. The one on the top hasn’t yet been washed, the one on the bottom has.

Next Chapter: Tender Loving Care